Linear motor-based seat shaker

In autonomous vehicles the driver will become a passenger. By ensuring a high level of ride comfort through active suspensions, the driver’s ability to perform various tasks such as reading, drawing and texting can be enhanced. A high-performance shaker rig has been designed to test the ride comfort improvement by means of various active suspensions under laboratory conditions.

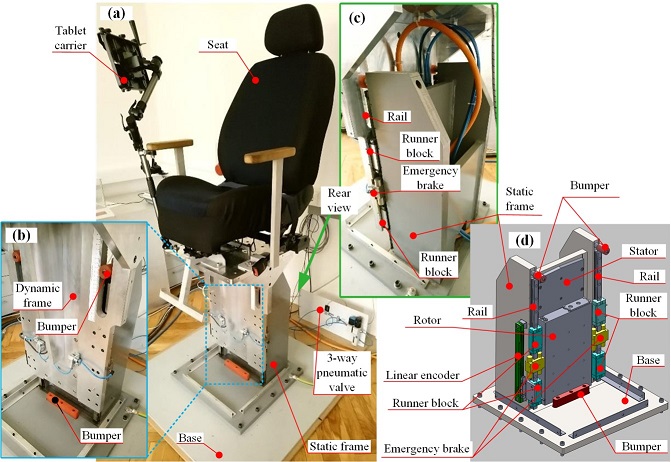

The design requirements have been derived from active suspension optimal control results, and they include maximum values of acceleration (±1 g), velocity (±1 m/s) and displacement (±100 mm), as well as the acceleration tracking bandwidth (at least 30; 50 Hz if possible). Three distinct designs have been considered (hydraulic cylinder, linear motor, and rotary motor with planetary spindle), and the design based on linear electric servo-motor has been selected and implemented.

The selected linear motor supplied by the firm HS-TEC can develop the maximum force of 6900 N for velocities up to 0.6 m/s, while at the velocity of 2 m/s the maximum force falls to 2610 N. The total mass of driver and rig moving parts ads up to maximum of 200 kg. Consequently, the maximum upward acceleration equals 2.5 g for speeds up to 0.6 m/s, and 1.8 g for speeds up to 1 m/s.

The shaker is equipped with highly accurate sensors for measurement of acceleration and displacement. Two capacitive DC response, high-sensitivity, low-noise, single-axis accelerometers, with the measurement range of ±2g and ±10g, are used for seat acceleration measurement. An absolute encoder with the measurement range of 220 mm and the accuracy grade of ± 5 µm is used for seat position and velocity measurements.

The shaker low-level control system handles the motor force reference, which is fed to a linear motor force/current controller integrated within a dedicated power converter with the rated power of 12 kW. The force reference is generated by a high-level control subsystem, which includes seat acceleration, velocity, and position controllers, whose references are generated off line by means of vehicle dynamics simulation. The control system is implemented on National Instruments CompactRIO FPGA-based acquisition and control hardware platform, and it is programmed and monitored through LABview software.

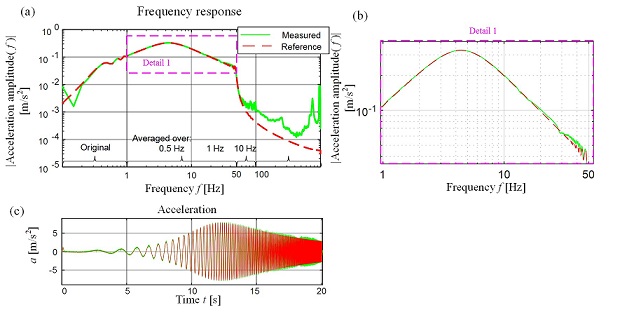

The core of the control system relates to acceleration feedforward and feedback control system, which provides excellent acceleration tracking in the band of 30 Hz, and very good tracking up to 50 Hz (see the responses given below). The control system includes a compensator of accelerometer measurement offset in order to prevent drift of seat position and velocity. A particular attention is paid to feedforward compensation of linear motor cogging force.

Publications

-

ASME Journal of Autonomous Vehicles and Systems, Vol. 1, No. 1, pp. 011004/1-21, 2021. -

Design of a Linear Motor-Based Shaker Rig for Testing Driver's Perceived Ride Comfort

Mechatronics, Vol. 75, pp. 102521/1-18, 2021. -

A Shaker Rig-Based Testing of Perceived Ride Comfort for Various Configurations of Active Suspensions

ASME Journal of Dynamic Systems, Measurement, and Control, Vol. 142, No. 11, pp. 114504/1-7, 2020.