SI engine

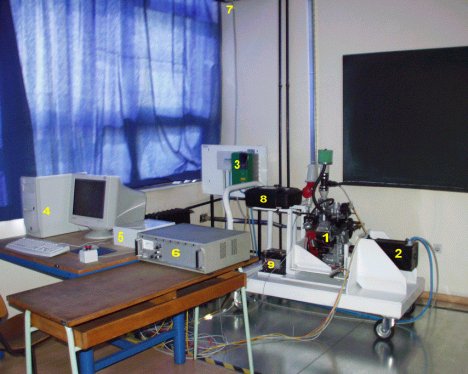

An experimental setup with a spark-ignited engine has been developed, in order to provide the possibility of validation of control-oriented engine models and verification of different engine and powertrain control strategies. The setup is equipped with a Briggs & Stratton, Vanguard V-Twin, four-strokes, two-cylinders, 14 HP gasoline engine. High-bandwidth AC servo-machine is a programmable load, an electronic throttle system and a variety of sensors have been added, as well as a control computer.

The following requirements have had the most significant influence on the main design characteristics of the experimental setup:

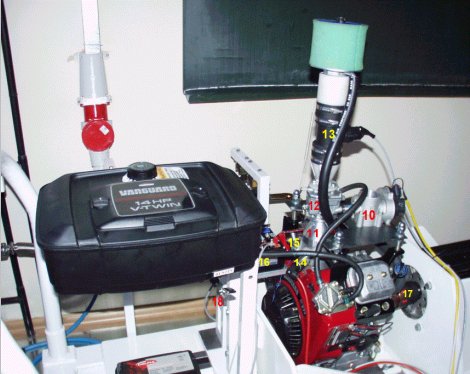

Possibility of detailed research of intake manifold dynamics. In order to provide experimental analysis of manifold thermal effects, different high-bandwidth sensors have been built in the manifold. These are pressure sensor (14), air temperature sensor (15), manifold wall temperature sensors, and throttle air mass flow sensor (13). Additional set of pressure and temperature sensors is built in one of the two engine runners. The original engine manifold has been reconstructed and enlarged (11), in order to provide space for sensors placement and to get manifold proportions, which are characteristic for automotive engines.

Dynamic load torque production. High-bandwidth electrical servosystem (2,3) is used to produce the engine load. A real-time dynamic load simulator as a part of the overall control program has been developed to make the engine load closer to that appeared in automotive powertrains. The load servosystem is also used as an engine starter, in order to avoid manual starting.

High-bandwidth, accurate and inexpensive engine torque measurement. In order to avoid expensive torque measurement shafts or flanges, the engine torque is measured indirectly, by using an inexpensive high-bandwidth force transducer (18) that measures the engine reaction force to the carrier construction. The engine is mounted to the base that can slide over the carrying surface, thus providing adjustable distance between the engine and the load machine for possible future installation of torque measurement shaft or any other driveline modifications.

Incorporation of electronic throttle. A commercial electronic throttle body (10) has been attached to the throttle plate of the engine carburetor (12). It is used as an external DC servosystem that provides accurate positioning of the throttle plate instead of the manual control through a steel string, thus providing computer control of engine and facilitating engine identification experiments. The steel string and a centrifugal engine speed controller have been permanently disconnected from the engine.

The experimental setup has been continuously developing, in order to make it better and in order to meet new research ideas.

- 1. B&S 14 HP V-Twin SI engine

- 2. Load servo-machine

- 3. Frequency converter

- 4. Control computer with data acquisition cards

- 5. Chopper and signal processing system

- 6. Force sensor amplifier

- 7. Cable to external braking resistors

- 8. Fuel tank

- 9. Battery (12 V, 45 Ah)

- 10. Electronic throttle body

- 11. Intake manifold extension

- 12. Carburetor

- 13. Air mass flow sensor

- 14. Pressure sensor

- 15. Temperature sensor

- 16. Thermocouple amplifier

- 17. Coupling

- 18. Force sensor

Fig. 1. Photography of SI engine experimental setup.

Publications

-

IEEE Transactions on Control System Technology, Vol. 17, No. 1, pp. 98-110, 2009. -

Application of Adaptive Kalman Filter for Estimation of Power Train Variables

SAE paper #2008-01-0585, SAE International Journal of Passenger Cars - Mechanical Systems, Vol. 1, No. 1, pp. 480-491, 2008.